硬碟硬體總架構

內容表格

沒有標頭原文 http://hddscan.com/doc/HDD_from_inside.html

作者:Artem Rubtsov

翻譯:OSSLab thx, frddie

這篇文章是比較新版的硬碟硬體架構.

1TB Seagate ST31000333AS

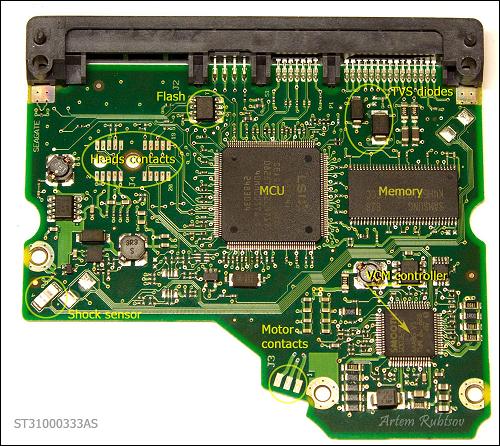

The fancy piece of green woven glass and copper with SATA and power connectors called Printed Circuit Board or PCB. PCB holds on place and wires electronic components of HDD. The black painted aluminum case with all stuff inside called Head and Disk Assembly or HDA. The case itself called Base.

Now let's remove PCB and see electronic components on the other side.

這塊綠色電路版 由SATA接頭、電源接頭組成的板子稱為印刷回路板,簡稱PCB。

PCB內含電路零組件。而黑色鋁質外殼內部組件稱為磁頭和硬碟組件,通稱為HDA。而鋁質外殼則稱為case。

現在拆卸PCB電路板並翻到反面,檢視反面的電子零組件。

硬碟PCB上最大控制器為MCU (Micro Controller Unit),MCU主要功能:

1.計算讀寫通道A/D,D/A

2.掌控全盤硬碟運作狀況.

3.MCU 另擔當的Protocol 與控制器間的轉換.

DDR DRAM 32MB ,實際上32MB Cache 部份會被硬碟挪用放入硬碟運作程式.

前言已敘述, 硬碟如同一個embedded system .需要載入OS運作.

下一個晶片是Voice Coil Motor controller,通稱VCM控制器。這是PCB板上最耗電的晶片,VCM控制器控制電機馬達的轉動及磁頭移動及定位,VCM控制器可在高達工作溫度

Flash晶片儲存部分的硬碟韌體,當你通電啟動硬碟時,MCU晶片會讀取Flash晶片內的資料到記憶體內並且開始編碼。如果缺少了這樣的步驟,硬碟無法運轉。有時候,某些廠牌的硬碟PCB板上並沒有Flash晶片,這表示原本Flash晶片內的資料已經寫入MCU晶片內了。

震動感應器

震動感應器可以感應硬碟多餘的震動並且傳送訊號給VCM控制器,VCM控制器接受訊號以後馬上停止並復位磁頭,在某些情況下,甚至會停止盤片轉動,這個理論上會保護硬碟免於受損,但是實際上並無法達成保護的目的,所以請好好保護硬碟,別摔落、碰撞!

在某些硬碟中,震動感應器可以感測輕微振動,而VCM控制器可以藉由震動感應器傳送的訊號調整磁頭的運動,這樣的硬碟通常都會配有兩組以上的震動感應器。

二級體

Another protection device called Transient Voltage Suppression diode or TVS diode. It protects PCB from power surges from external power supply. When TVS diode detects power surge it fries itself and creates short circuit between power connector and ground. There are two TVS diodes on this PCB for 5V and 12V protection.

Let's take a quick look on HDA

另外一個保護的零組件是瞬態電壓抑制二極管(Transient Voltage Suppression diode)或簡稱為TVS二極體。此組件可以保護PCB板免於連接電源時造成的瞬間電流激增,在這種情況下,TVS二極體會燒毀造成電源接頭及接地之間的電路短路。硬碟都配有兩組TVS二極體,一組5V電流一組12V電流。

You can see motor and heads contacts which were hiding under the PCB. There is also small almost unnoticeable hole on HDA. This hole called Breath hole. You maybe heard old rumor which says that HDD has vacuum inside, well that is not true. HDD uses Breath hole to equalize pressure inside and outside HDA. From the inside Breath hole closed by Breath filter to make air clean and dry.

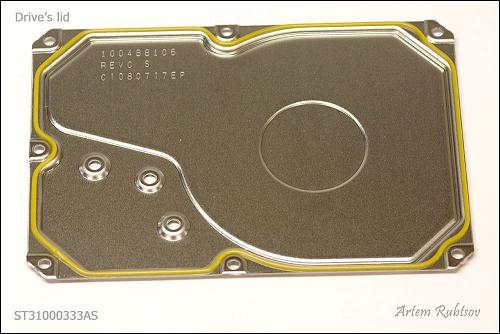

Now it is time to take a look under the hood. We are going to remove the drive's lid.

在上圖中,你可以看到隱藏在PCB板下的馬達及磁頭接頭,另外在HDA上還有一個小到難以注意的小孔叫做進氣孔。你可能聽過一個謠言說硬碟內是真空狀態,這並不是真的。硬碟利用這個進氣孔來平衡HDA外部跟內部的壓力,而硬碟可以透過進氣孔過濾器關閉內部的進氣孔來達到內部空氣乾燥及乾淨。

現在讓我們來移開硬碟上蓋並看在其之下的構造。

The lid itself is nothing interesting. Just a piece of steel with rubber cord for dust protection. Finally we are going to see HDA from inside.

上蓋本身並無值得介紹之處,就是一塊周圍有防塵橡膠圍繞的鐵片。

打開上蓋之後,終於可以從內部觀察HDA。

Precious information stored on platters, you can see top platter on the picture. Platters made of polished aluminum or glass and covered with several layers of different compounds including ferromagnetic layer which actually stores all the data. As you can see part of the platter covered with the Dumper. Dumpers sometimes called as Separators located between platters, they reduce air fluctuations and acoustic noise. Usually dumpers made of aluminum or plastic. Aluminum dumpers better for cooling air inside HDA.

珍貴的資訊是儲存在碟片上,你可以從上圖看到最上層的碟片。碟片是由打磨過的鋁片或是由覆蓋數層包含鐵磁材質之複合塗料的玻璃所製成的,而後者的資料就儲存在包含鐵磁材質之複合塗料中。

你可以看到部分的碟片被磁盤架蓋住了。磁盤架有時候也稱為Separators located between platters,磁盤架可以減少空氣的波動及運作的噪音。通常磁盤架是由鋁質或塑膠材料製程,而前者則在冷卻硬碟內部方面有較好的效果。

Next picture shows platters and dumpers from the side

下圖顯示出碟片跟磁盤架的相關位置。

Heads mounted on Head Stack Assembly or HSA. This drive has parking area closer to the spindle and if power is not applied on a drive, HSA normally parked like on the picture.

磁頭是由數個讀取頭所組合而成的,當硬碟未通電的狀態下,磁頭通常停留在靠近在電機馬達的地方。下圖顯示出正常讀取頭的位置。

HDD is a precision mechanism and in order to work it requires very clean air inside. During work HDD may create some very small particles of metal and oil inside. To clean air immediately a drive uses Recirculation filter. This hi-tech filter permanently collects and absorbs even finest particles. The filter located on the way of air motion created by platters rotation.

硬碟是一個精密運作的機器,因此運作時必須要非常乾淨無塵的空氣。而在硬碟運作的過程中,硬碟會在內部產生非常細小的金屬微粒跟油質。

為了在乾淨無塵的環境下工作,硬碟會使用裝置Recirculation filter來過濾空氣,這個高科技的過濾器長時間不間斷地收集雜質,即使是最細小的微粒也不例外。過濾器的位置是位在碟片旋轉所產生的氣流路徑上。

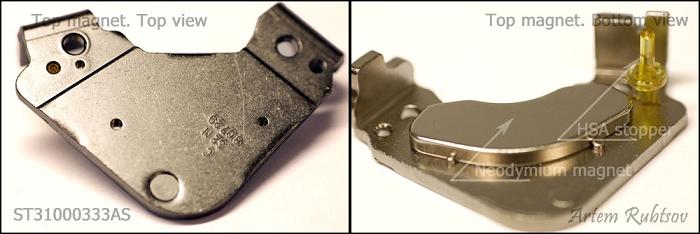

Now we are going to remove top magnet to see what is under.

現在我們移開磁鐵來看他內部的構造。

HDDs use very strong Neodymium magnets. Such a magnet is so strong it could lift up to 1300 times its own weight, so don't put your fingers between magnet and steel or another magnet - it can develop great impact. You can see on this picture there is a HSA stopper on the magnet. HSA stoppers limit HSA movements, so heads wouldn't bang on the platters clamp and on the other side they wouldn't just fly off the platters. HSA stoppers may have different construction but there are always two of them and they always present on modern HDDs. On this drive the second HSA stopper located on HDA under the top magnet.

And here is what you may see under the top magnet.

There is the other HSA stopper. And you also can the second magnet. The Voice coil is a part of HSA, Voice coil and the magnets form Voice Coil Motor or VCM. VCM and HSA form the Actuator - a device which moves the heads. Tricky black plastic thingy called Actuator latch is a protection device - it will release HSA when drive un-parking (loading) heads normally and it should block HSA movements in the moment of impact if drive was dropped. Basically it protects (should, at least) heads from unwanted movements when HSA is in parking area.

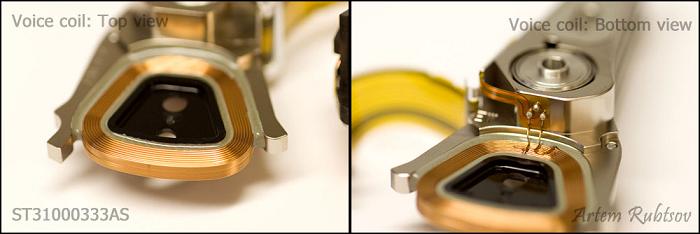

On the next step we going to take out HSA

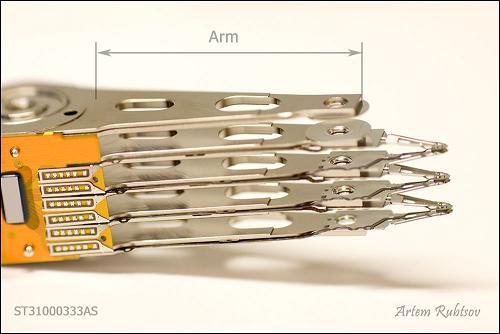

HSA has precision bearing to make movements nice and smooth. The biggest part of HSA milled from piece of aluminum called the Arm. Heads Gimbal Assembly or HGA attached to the Arm. HGAs and Arms usually produced on different factories. Flexible orange widget called Flexible Printed Circuit or FPC joins HSA and plate with heads contacts.

Let's take closer look on each part of HSA.

Voice coil connected to FPC

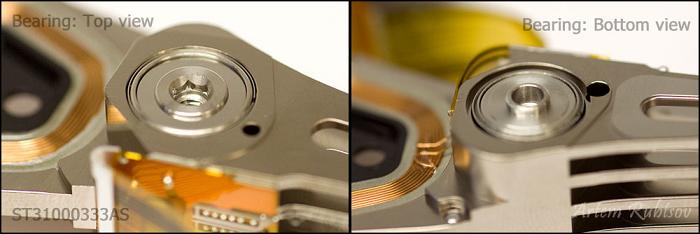

Here is the bearing

On the next picture you can see HSA contacts

The gasket makes connection airtight. The only way for air to go inside HDA is through the breathing hole. On this drive contacts covered with thin layer of gold, for better conductivity.

This is the classic definition of the arm. Sometimes by the arm imply the whole metal piece of HSA.

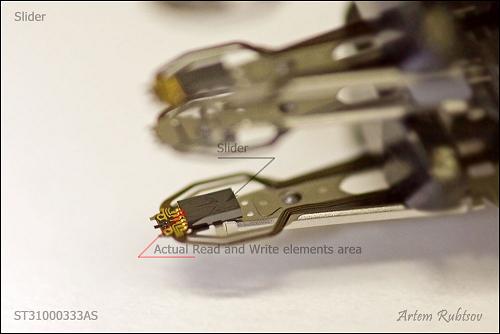

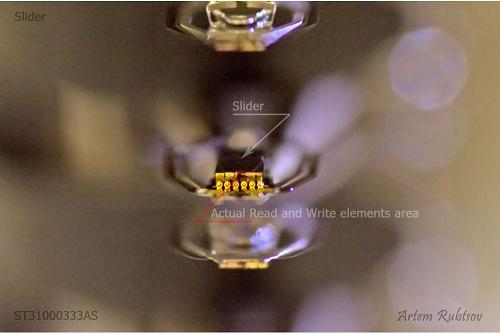

The black small things at the end of HGAs called Sliders. In many sources you can find that sliders claimed as actual heads but a slider itself is not a head it's a wing which helps read and write elements fly under the platter's surface. Heads flying height on modern HDDs is about 5-10 nanometers. For example: an average human's hair is about 25000 nanometers in diameter. If any particle goes under the slider it could immediately overheat (because of friction) the heads and kill them that's why clean air inside HDA is so important. The actual read and write elements located at the end of the slider and they are so small that can only be seen under a good microscope.

As you can see slider's surface is not flat, it has aerodynamical grooves. These grooves help a slider fly on the certain height. Air under the slider forms Air Bearing Surface or ABS. ABS makes slider fly almost parallel to the platter's surface.

Here is another picture of the slider

You can clearly see heads contacts.

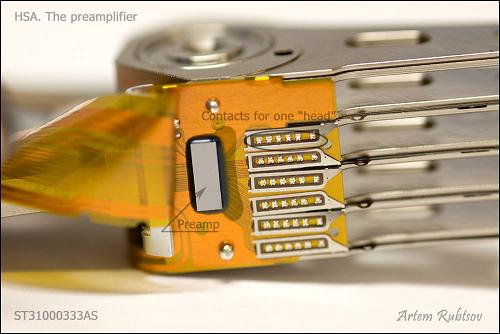

There is very important part of HSA which we haven't discussed yet. It called the preamplifier or preamp. The preamp is a chip, which controls heads and amplifies signals from/to them.

The reason why the preamp located inside HDA is simple - signals from heads are very weak and on modern HDDs have more than 1GHz frequency, if take the preamp out of HDA such weak signals wouldn't survive, they will disappear on the way to PCB.

The preamp has much more tracks going to the heads (right side) than to the HDA (left side), it's because HDD can work only with one "head" (pair of read an write elements) at a time. HDD sends control signals to the preamp and the preamp selects the head which HDD needs at the current moment. This HDD has six contacts per "head", why so many? One contact is for ground, other two for read and write elements. Other two for microactuators - special piezoelectric or magnetic devices which can move or rotate slider, it helps tune up heads position under a track. And finally the last contact is for a heater. The heater can help adjust heads flying height. The heater can heat the gimbal - special joint which connects slider to HGA, the gimbal made from two stripes of different alloys with different thermal expansion. Once gimbal got heated it bents itself toward platter's surface and this action reduces flying height. After cooling down the gimbal straights itself.

Enough about heads, let's continue disassembling. We going to remove top dumper.

That's how it looks

And next picture shows HDA without the top dumper and HSA

Now the top platter is not covered, you also can see the bottom magnet

Let's move further and remove the platters clamp

The platters clamp squeezing platters into the platters packet, so they wouldn't move.

Platters sitting on the spindle hub, the platters clamp creates enough friction to hold platters on the hub when spindle rotates.

Now when nothing holding platters on the hub we are going to remove the top platter and next picture shows what we may see under.

Now you see how platters packet has room for heads - platters laying on spacer rings. You can see the second platter and the second dumper.

The spacer ring is a precision detail made of non-magnetic alloy or polymer. Let's take it out.

Finally we are going to shake out the rest of the stuff from HDA and see the base

That's how the breath filter looks. And the breath hole located right under the breath filter. Let's see the breath filter closer.

Because air from outside definitely has dust the breath filter has several layers of filtration and it's much thicker than recirculation filter, it also may have some silica gel inside to reduce air moisture.